Why fast cooling is important for yogurt ?

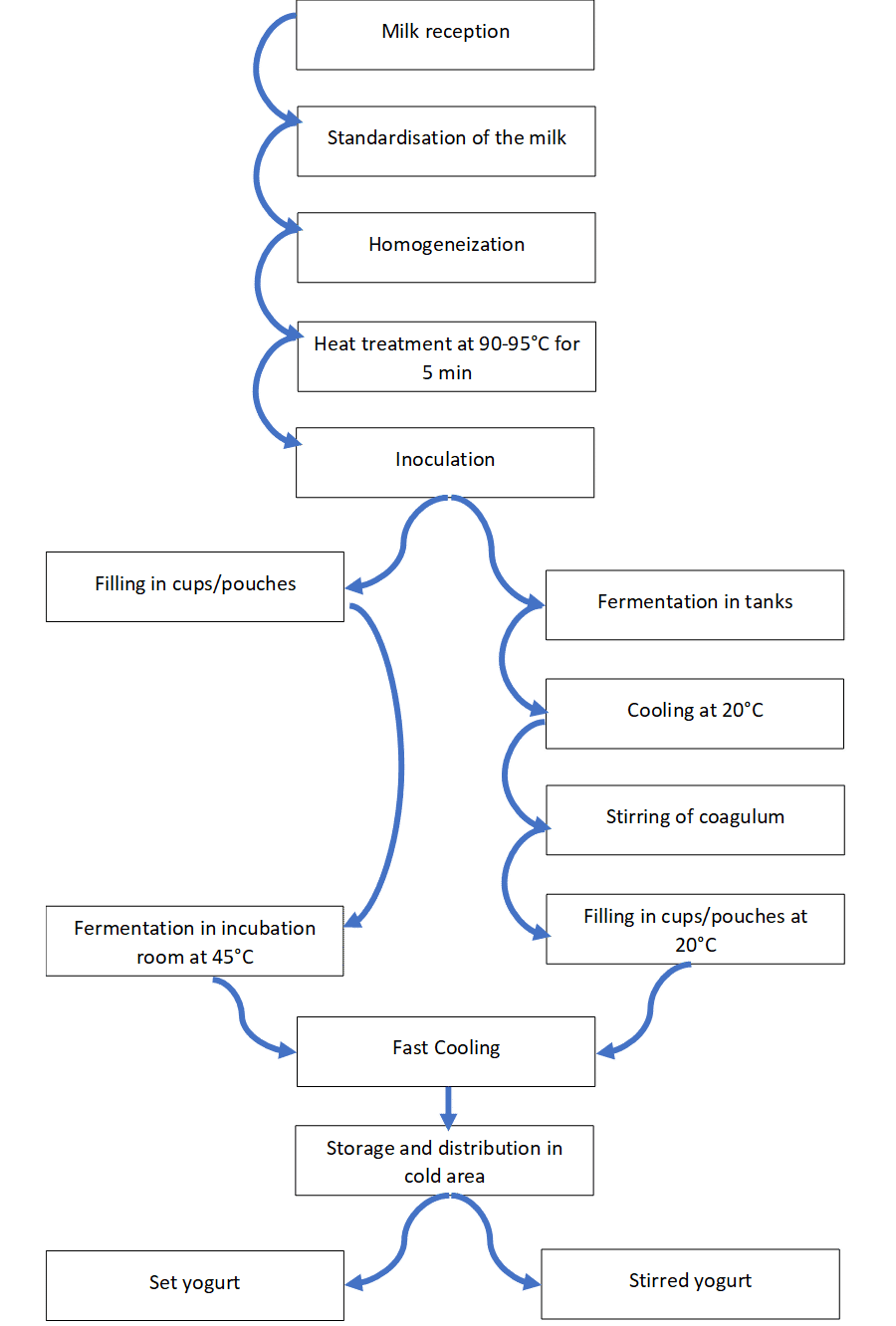

The continuous improvement of the quality of fresh products such as set yogurt and the standardization of the process is at the heart of manufacturers’ concerns. So how do we improve the quality of yogurt?

Yogurts must be cooled as quickly as possible to guarantee a perfect product in terms of:

- Taste,

- Texture,

- Acidity,

- Shelflife

In addition, to integrate optimally into the manufacturing process, cooling must be done after palletizing. Among other things, this reduces the size of the cooling equipment and reduces energy consumption.

The ideal blowing temperature is between 0 and 2 ° C. Indeed, a negative temperature increases energy consumption and creates a risk of freezing of products on the periphery, causing major quality problems.

For example, for set yogurts, fast cooling of pallets allows :

- To stop the growth, multiplication and activity of lactic acid bacteria (eg: Streptococcus thermophilus and Lactobacillus delbrueckii subsp.bulgaricus);

- Control the evolution of the pH by stopping the acidification (eg final pH = 4.6);

- Finalize the lactic coagulation and obtain a perfect “soft gel” resulting in a good texture;

- Reduce the presence of free water molecules;

- Standardize the temperature of the yogurt pots in the pallet (eg: final temperature = 4 +/- 2 ° C);

- Better organoleptic qualities;

- Have a good appearance;

- Improve shelflife.

Therefore homogeneous and uniform cooling is essential. It allows a standardization of the process guaranteeing a homogeneous quality throughout the year.